Brushless motors have become increasingly popular in recent years due to their many advantages over traditional brushed motors.

Brushless motors have become increasingly popular in recent years due to their many advantages over traditional brushed motors.

One question that arises is whether brushless motors wear out over time or not.

In this article, we’ll take a closer look at the lifespan and durability of brushless motors.

Table of Contents

What Are Brushless Motors

Advantages of Brushless Motors

Advantages of Brushless Motors

Brushless motors use magnets to create motion, unlike traditional brushed motors that rely on brushes for electricity transfer.

This lack of physical contact between parts makes brushless motors more efficient and longer lasting.

- Utilizes magnetism instead of brushing

- Greater efficiency thanks to minimal energy loss

- Smaller size & weight; less noise

- Reduced maintenance cost

Brushless motors are more efficient due to reduced friction and energy loss without the need for brushes or commutators.

They are also smaller, lighter, and quieter than brushed options with significantly lower maintenance costs since there aren’t any moving parts making contact.

Brushless motors are the future of electric motors.

With their superior efficiency and durability, brushless motors are becoming increasingly popular in a variety of applications, including drones, electric vehicles, and power tools.

They are also more environmentally friendly due to their reduced energy consumption and longer lifespan.

Investing in brushless motors is a smart choice for any industry.

Overall, brushless motors offer numerous advantages over traditional brushed motors, making them a smart choice for any industry looking to improve efficiency, reduce maintenance costs, and increase durability.

The Difference Between Brushed And Brushless Motors

Brushed vs Brushless Motors: Which is Better?

Brushed vs Brushless Motors: Which is Better?

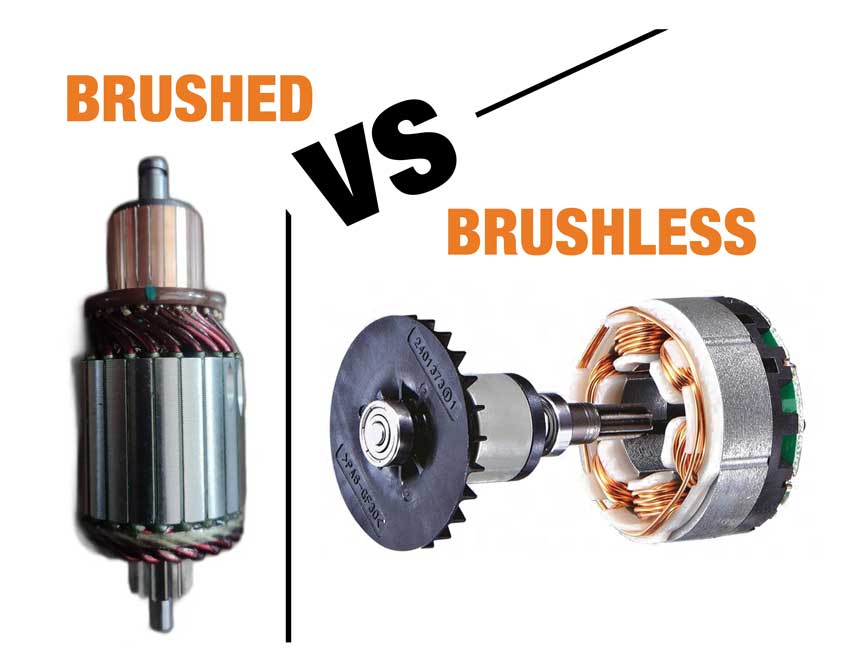

Brushless motors offer numerous advantages over traditional brushed motors.

The primary difference lies in their operation: while a brushed motor relies on two metal brushes that create electrical resistance and cause wear, brushless engines use electronic signals to run without physical contact.

Unlike carbon-based or soft copper brushes found in brushed engines, brushless ones don’t require replacement due to wear and tear caused by frictional movements inside the engine.

Instead of relying on contacts between parts, they utilize magnetic fields and permanent magnets for power generation with minimal heat loss.

Brushless motors are more efficient, reliable, and durable than brushed motors.

5 Key Differences Between Brushed and Brushless Motors

- Brushes must be periodically replaced in a brushed motor

- Brushed motors generate more electromagnetic interference than brushless ones

- A higher number of poles can increase torque output for both types of engines but is easier to achieve with brushless designs

- While both types have similar efficiency at low speeds, high-speed performance favors the superior design of a brush-free system like those used by modern electric cars’ drive systems

- Brushes limit maximum RPMs because they cannot handle as much current as required when running faster compared against non-brushed counterparts which do not face this limitation

Brushless motors are the future of electric motors.

Brushed Motor Wear And Tear

How to Maintain Brushed Motors

How to Maintain Brushed Motors

Brushed motors are prone to wear and tear, which can lead to reduced performance over time.

The brushes inside the motor can become worn down due to constant contact with the commutator.

This wear can produce excess debris that could clog up other parts of your motor or cause damage if left unchecked.

Therefore, regular maintenance and cleaning are crucial when dealing with brushed motors.

Brush Wear Maintenance Tips

- Inspect Regularly: Regular inspection is necessary to detect signs of excessive wear on the brushes.

- Replace Brushes: New brushes will eventually be required for brushed motors.

- Clean Debris: Cleaning out any debris from within a brushed motor helps extend its lifespan significantly.

- Avoid Overuse: Avoid running excessively worn-down brush since it could lead to more severe damages.

Always refer to the manufacturer guidelines for proper care and replacement procedures.

By following these simple maintenance tips, you can extend the lifespan of your brushed motor and keep it running smoothly for longer.

Regular maintenance and cleaning are crucial when dealing with brushed motors.

Don’t let wear and tear get the best of your brushed motor.

Take care of it, and it will take care of you.

How Do Brushless Motors Work

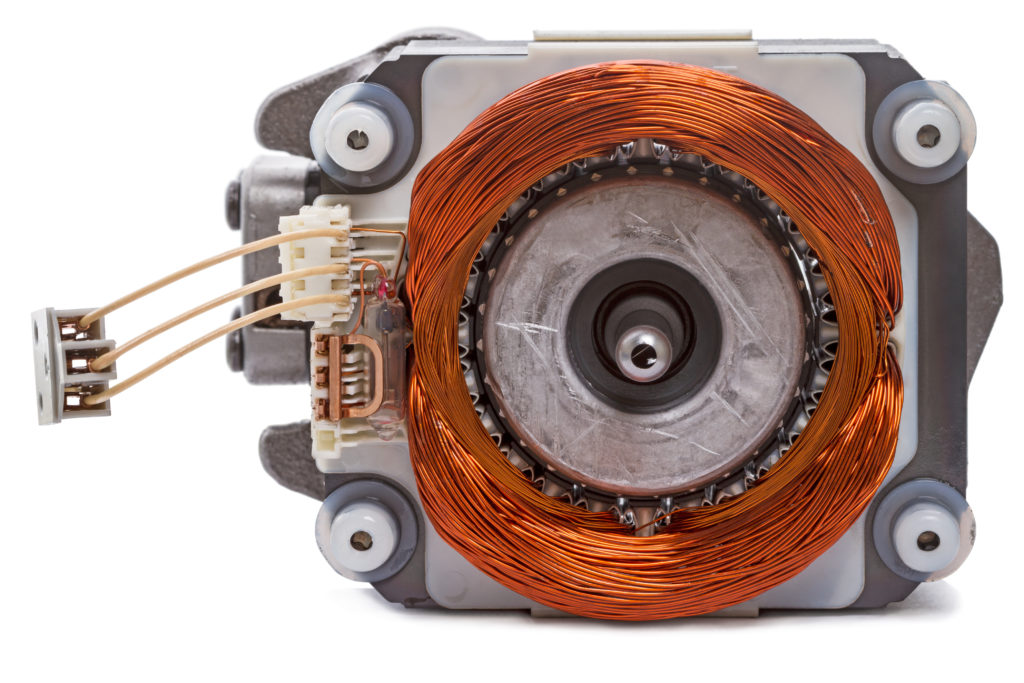

How Brushless Motors Work

How Brushless Motors Work

Brushless motors are widely used in drones, electric vehicles, and power tools.

They are different from brushed motors that rely on physical brushes for motion.

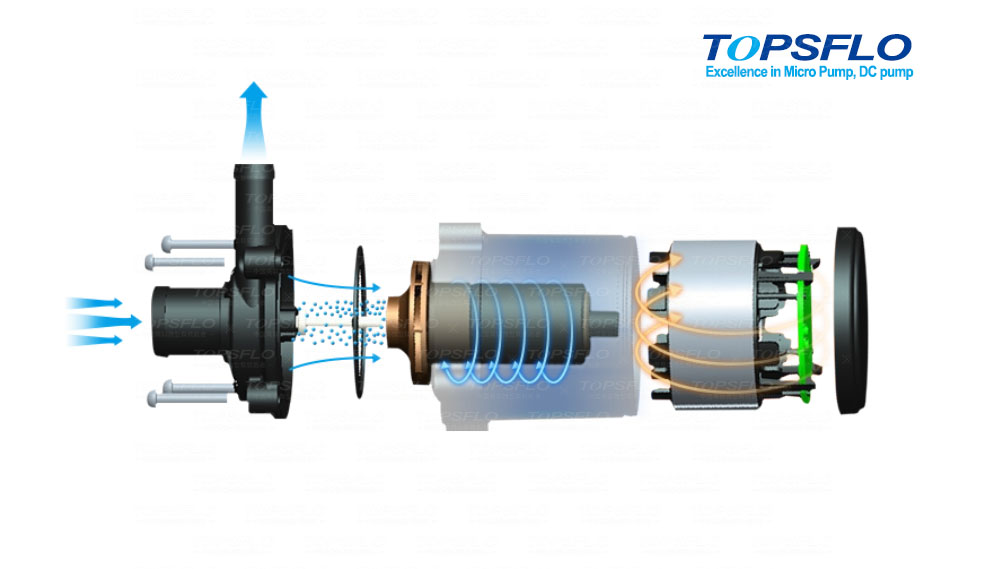

Instead, brushless motors use electronic controllers to manage current flow through wires wrapped around a rotor.

The controller tracks the magnets’ position on the rotor and sends signals to switch power between different electromagnets surrounding it.

This creates a rotating magnetic field that drives the shaft and produces torque for movement.

Brushless motors have longer lifespans than brushed ones because there are no brushes wearing out over time.

Key Points

- Brushless motors use an electronic controller instead of physical brushes

- The controller sends signals to different electromagnets surrounding the rotor

- These currents create a rotating magnetic field driving movement

Brushless motors are more efficient, produce less noise, and require less maintenance than brushed motors.

Brushless motors are more efficient, produce less noise, and require less maintenance than brushed motors.

They are also more expensive, but their benefits outweigh the cost in many applications.

Brushless motors are becoming increasingly popular in various industries due to their reliability and performance.

Brushless motors are ideal for applications that require high speeds, high torque, and precise control.

Brushless motors are ideal for applications that require high speeds, high torque, and precise control.

They are commonly used in drones, electric vehicles, and power tools, but their applications are not limited to these industries.

Potential Causes Of Wear In Brushless Motors

Preventing Brushless Motor Failure

Preventing Brushless Motor Failure

Brushless motors can experience wear due to excessive heat generated during long operation, which impacts components like bearings and windings.

Overloading the system beyond its capacity also causes fatigue on elements such as shafts or gears leading to breakdown.

Improper installation procedures including loose connections may damage internal parts resulting in increased operating temperatures that reduce efficiency while increasing wear tear risk.

Regular maintenance is crucial to prevent premature failure.

Proper Installation

Proper wire routing during installation process ensures optimal performance and protects delicate internal components from damage caused by vibrations or other external factors.

Protecting your motor with a protective cover helps keep it safe from dust, debris, moisture and other environmental hazards that could cause harm over time.

Maintenance Tips

- Regularly clean the motor to prevent dust buildup

- Check for loose connections and tighten as necessary

- Inspect the motor for signs of wear and tear

- Replace worn out components promptly

By following these tips, you can extend the lifespan of your brushless motor and ensure optimal performance.

Reasons Why Brushless Motors Tend To Last Longer Than Brushed Ones

Why Brushless Motors are Better Than Brushed Ones

Why Brushless Motors are Better Than Brushed Ones

Brushless motors have fewer moving parts, making them last longer than brushed ones.

Brushed motors use brushes and commutators, creating friction that wears them down over time.

- Brushless motors lack brushes and commutators, resulting in less wear and tear

- Brushless motors have an efficient design that generates less heat compared to brushed ones, allowing them to run cooler without overheating or suffering from performance issues

- The sealed construction of brushless motors makes them more reliable while reducing electrical noise caused by physical contacts between two components

- Brushless motors offer a superior power-to-weight ratio due to their lightweight design compared to brushed counterparts

Efficient cooling systems highlight increased durability in brushless motor designs as well as greater efficiency leading directly towards better overall performance.

Brushless motors are the future of motor technology, offering longer lifespan, better performance, and greater reliability.

Investing in brushless motors is a smart choice for anyone looking for a high-quality, long-lasting motor that can handle a variety of applications.

Factors That Affect The Lifespan Of A Brushless Motor

Factors Affecting Brushless Motor Lifespan

Factors Affecting Brushless Motor Lifespan

A brushless motor’s lifespan is impacted by various factors.

Quality materials used in construction play a crucial role, as high-grade components last longer than lower-quality ones.

Regular maintenance and cleaning also significantly prolong the motor’s life span.

Environmental conditions such as heat or moisture exposure can cause premature wear and tear on your brushless motor.

Key Points

Here are some key points that affect a brushless motor’s lifespan:

- Material quality: High-grade components last longer than lower-quality ones.

- Maintenance and cleaning: Regular maintenance and cleaning significantly prolong the motor’s life span.

- Environmental conditions: Heat or moisture exposure can cause premature wear and tear on your brushless motor.

- Usage intensity and frequency: Heavy usage can shorten the lifespan of your brushless motor.

It’s important to keep these factors in mind when using and maintaining your brushless motor to ensure it lasts as long as possible.

Regular maintenance and cleaning significantly prolong the motor’s life span.

Make sure to clean your brushless motor regularly and keep it in a dry, cool environment to prevent premature wear and tear.

Signs Your Brushless Motor Might Be Wearing Out

Signs of a Worn-Out Brushless Motor

Signs of a Worn-Out Brushless Motor

If you’re experiencing decreased performance and weaker output, your brushless motor may be worn out.

This could be due to worn bearings or damaged rotor surfaces that cause internal components to wear down over time.

Another indication is increased heat and noise produced during use.

If the motor feels hotter than usual after running, it may have problems with cooling systems or insufficient airflow around sensitive parts.

Remember, a worn-out brushless motor can lead to decreased performance and weaker output, so it’s important to identify the signs early on.

5 Key Indications of a Failing Brushless Motor

- Reduced Performance: Slower acceleration speeds and lower top-end speed.

- Decreased Torque: Gradual decrease in power output on hills.

- Extreme Vibrations: Unusual amounts felt while operating the device.

- Increased Heat Production: Motor feels hot even when not under heavy load.

- Strange Noises Emitted During Use

Don’t ignore these signs.

If you notice any of these indications, it’s time to replace your brushless motor.

How To Maintain Your Brushless Motor For Maximum Longevity

Maximizing the Lifespan of Your Brushless Motor

Maximizing the Lifespan of Your Brushless Motor

Proper care and maintenance are crucial to ensure the longevity of your brushless motor.

Follow these tips:

- Clean any dirt or debris around the motor with compressed air after every use or at least once a month.

- Tighten all screws properly before using it again.

- Avoid overloading by staying within its recommended capacity range.

- Lubricate bearings if required for extra protection from wear and tear.

- Store in a dry cool place away from direct sunlight when not being used.

By taking these simple steps to maintain good condition, you can ensure maximum longevity for your brushless motor device!

Common Issues That Can Cause Premature Failure In A Brushless Motor

5 Common Causes of Premature Brushless Motor Failure

5 Common Causes of Premature Brushless Motor Failure

Brushless motors can fail prematurely due to several common issues.

Here are five key takeaways:

- Overheating: Occurs when the motor is overloaded or not properly ventilated, causing heat buildup that damages internal components and ultimately leads to failure over time.

- Low-Quality Materials: Subpar materials may seem cost-effective at first but increase the likelihood of unexpected failures later on.

- Inadequate Lubrication: Reduces lifespan and can cause breakdowns in brushless motors.

- Excessive Vibration: Leads to malfunctioning parts and can cause early breakdowns in brushless motors.

- Normal Wear and Tear: Requires maintenance and can cause natural breakdowns in brushless motors over time.

Remember, taking care of your brushless motor can help prevent premature failure and save you time and money in the long run.

By understanding these common causes of premature brushless motor failure, you can take steps to prevent them and ensure your motor lasts as long as possible.

Don’t let these issues catch you off guard – be proactive and take care of your motor to avoid unexpected breakdowns.

When Is It Time To Replace A Failing Or Worn Out Brushed Or Brushelesss Motor

When to Replace Your Brushed/Brushless Motors

To maintain efficiency and longevity, it’s crucial to replace failing or worn-out brushed/brushless motors.

Unusual noise from the motor accompanied by a significant reduction in performance may indicate that it’s time for a change.

Inadequate power supply can also cause problems with smooth operation and reduced lifespan.

Frequent breaks or overheating of brushes are good indicators that your motor needs replacing soon.

Excessive heat emanating from brushless motors despite normal usage is another sign of wear requiring replacement.

Quick Tip: Don’t wait until it’s too late.

Regularly check your motors for signs of wear and tear to avoid costly downtime.

5 Signs You Need to Replace Your Motors

- Reduced speed: Decrease in overall machinery rotation/speed.

- Heat emission: Abnormal levels of heat coming out during regular use.

- Noise increase: Increase in unusual sounds produced while operating machinery.

- Wear & tear on parts

- Increased energy consumption

Quick Tip: Replacing your motors at the first sign of trouble can save you time and money in the long run.

Regular maintenance and replacement of worn-out motors can help keep your machinery running smoothly and efficiently.

Don’t let failing motors slow down your productivity.

Keep an eye out for these signs and replace your motors as needed.

What Advancements We May See With Future Iterations Of These Technologies

The Future of Brushless Motor Technology

The Future of Brushless Motor Technology

The future of brushless motor technology promises exciting advancements.

Miniaturization may lead to smaller, more powerful motors for a wider range of applications – from lighter drones to efficient electric vehicles.

Materials science innovations will create stronger yet lighter components, improving performance and efficiency across industries.

Advancements We Can Expect

- Smaller but more powerful motors through miniaturization.

- Higher quality outputs driven by materials science innovations.

- Greater power and reliability with improved energy storage mechanisms.

- Real-time data provided by enhanced sensors.

With these advancements, we can expect to see a significant impact on industries such as:

- Automotive

- Aerospace

- Robotics

- Consumer electronics

Smaller, more powerful motors will allow for greater design flexibility and efficiency in these industries.

Additionally, the improved energy storage mechanisms will lead to longer-lasting and more reliable products.

As materials science innovations continue to improve, we can expect to see:

Advantages of Brushless Motors

Advantages of Brushless Motors Brushed vs Brushless Motors: Which is Better?

Brushed vs Brushless Motors: Which is Better? How to Maintain Brushed Motors

How to Maintain Brushed Motors How Brushless Motors Work

How Brushless Motors Work Preventing Brushless Motor Failure

Preventing Brushless Motor Failure Why Brushless Motors are Better Than Brushed Ones

Why Brushless Motors are Better Than Brushed Ones Factors Affecting Brushless Motor Lifespan

Factors Affecting Brushless Motor Lifespan Signs of a Worn-Out Brushless Motor

Signs of a Worn-Out Brushless Motor Maximizing the Lifespan of Your Brushless Motor

Maximizing the Lifespan of Your Brushless Motor 5 Common Causes of Premature Brushless Motor Failure

5 Common Causes of Premature Brushless Motor Failure The Future of Brushless Motor Technology

The Future of Brushless Motor Technology