Table of Contents

Boost Your Speed: How to Make a 17.5 Brushless Motor Faster

For those who are passionate about remote control car racing, having a fast motor is crucial. A 17.5 brushless motor is a popular choice for many racers, but sometimes it may not be fast enough to keep up with the competition. Fortunately, there are ways to make a 17.5 brushless motor faster, and this article will cover some of the most effective methods.

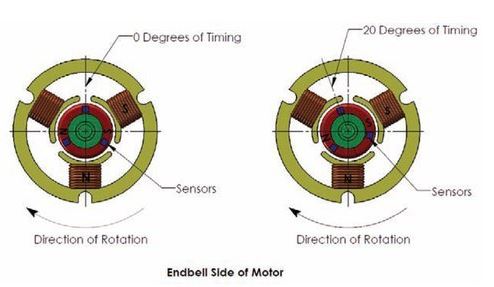

One way to increase the speed of a 17.5 brushless motor is by adjusting the timing. The timing refers to the relationship between the rotor and stator in the motor, and by changing this relationship, the RPM of the motor can be increased. Another method is to change the gearing of the motor, which involves altering the size of the pinion gear or spur gear to adjust the motor’s torque and speed.

It’s important to note that making a brushless motor faster can be a delicate process, and it’s crucial to have a good understanding of the motor’s components and how they work together. With that said, let’s dive into some of the most effective ways to make a 17.5 brushless motor faster and achieve that winning edge on the track.

Understanding Brushless Motors

Brushless motors are a type of electric motor that are used in a variety of applications, from RC cars to industrial machinery. Unlike traditional brushed motors, brushless motors use a series of magnets to create rotational motion, rather than brushes that come into contact with the rotor.

There are several advantages to using a brushless motor over a brushed motor. First, brushless motors are more efficient, meaning they can convert more of the electrical energy into mechanical energy. Second, they have a longer lifespan, as there are no brushes to wear out over time. Third, brushless motors can provide more precise control over the speed and torque of the motor.

Brushless motors are made up of two main parts: the rotor and the stator. The rotor is the rotating part of the motor, and is made up of a series of permanent magnets. The stator is the stationary part of the motor, and is made up of a series of electromagnets. When an electrical current is applied to the stator, it creates a magnetic field that interacts with the magnets on the rotor, causing it to rotate.

There are several factors that can affect the performance of a brushless motor, including the number of turns in the windings, the size and shape of the magnets, and the timing of the electrical pulses that are sent to the motor. By understanding these factors and how they affect the motor’s performance, it is possible to make adjustments that can improve the speed and torque of the motor.

Factors Affecting Motor Speed

Several factors can affect the speed of a brushless motor. One of the most important factors is the voltage that is applied to the motor. The speed of the motor is directly proportional to the voltage applied to the phases. In other words, the higher the voltage, the faster the motor will spin.

Another factor that affects motor speed is the torque on the rotor shaft. The speed of the motor is inversely proportional to the torque on the rotor shaft when it is set up for constant power. This means that if the torque increases, the speed of the motor will decrease.

The size of the rotor is also an important factor in the speed of the motor. A larger diameter rotor can increase the motor’s torque, but it can also decrease the motor’s speed. It is important to note that the size of the rotor must comply with the guidelines set by the regulatory body for the particular type of motor being used.

The number of poles in the motor also plays a role in the motor’s speed. A motor with more poles will have a lower speed than a motor with fewer poles. This is because a motor with more poles will have a lower Kv rating, which is the number of revolutions per volt.

The type of magnets used in the motor can also affect the motor’s speed. Neodymium magnets are commonly used in brushless motors because they have a high magnetic flux density. This means that they can generate a stronger magnetic field, which can increase the motor’s speed.

Upgrading Motor Components

Upgrading the various components of a 17.5 brushless motor is a great way to increase its speed and performance. Some of the key components that can be upgraded include:

- Rotor: The rotor is the spinning part of the motor that generates the magnetic field. Upgrading to a high-quality rotor with stronger magnets can increase the motor’s power and speed.

- Stator: The stator is the stationary part of the motor that houses the windings. Upgrading to a stator with more windings can increase the motor’s torque and power.

- Bearings: Upgrading to high-quality bearings can reduce friction and increase the motor’s efficiency, resulting in better performance and longer lifespan.

- ESC: The electronic speed controller (ESC) controls the motor’s speed and power output. Upgrading to a more advanced ESC with better programming options can result in smoother acceleration and better overall performance.

When upgrading motor components, it’s important to ensure that all the components are compatible with each other and with the motor’s specifications. It’s also important to follow the manufacturer’s instructions carefully and to use high-quality components from reputable brands.

While upgrading motor components can be an effective way to increase a 17.5 brushless motor’s speed and performance, it’s important to keep in mind that there are limits to how much improvement can be achieved through upgrades alone. Other factors, such as the vehicle’s weight, gearing, and battery voltage, can also have a significant impact on the motor’s performance.

Programming ESC for Higher Speed

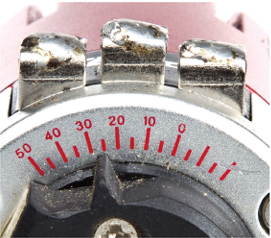

To make a 17.5 brushless motor faster, the programming of the ESC is crucial. The ESC is responsible for controlling the speed and power of the motor, and it can be programmed to achieve higher speeds. One way to program the ESC is to adjust the timing. The timing marks on the end of the motor’s can indicate a range of stator/sensor timing that adjusts how the motor’s RPM builds throughout its powerband. Adjusting the timing can help increase the motor’s speed. Another way to program the ESC is to adjust the throttle curve. The throttle curve determines how much power is delivered to the motor at different throttle positions. By adjusting the throttle curve, you can increase the power delivered to the motor and achieve higher speeds. It is also important to ensure that the ESC is properly calibrated. Calibration ensures that the ESC is accurately measuring the throttle position and delivering the appropriate amount of power to the motor. Improper calibration can result in reduced performance and slower speeds. Overall, programming the ESC is an important step in making a 17.5 brushless motor faster. By adjusting the timing, throttle curve, and ensuring proper calibration, you can increase the motor’s speed and performance.

Tips for Maintaining High Motor Performance

After tuning your brushless motor to achieve maximum performance, it’s important to maintain it properly to ensure that it continues to perform at its peak. Here are some tips for maintaining high motor performance:

- Keep it clean: Dirt and debris can build up on the motor and cause it to overheat. Regularly clean the motor with a soft brush or compressed air to remove any debris that may have accumulated.

- Monitor the temperature: Keep an eye on the motor temperature while running. If it gets too hot, it can damage the motor or reduce its performance.

- Check the bearings: Bearings can wear out over time and cause the motor to run less efficiently or even seize up. Check the bearings regularly and replace them if necessary.

- Inspect the wiring: Make sure the wiring is securely connected and not damaged. Damaged wiring can cause the motor to malfunction or even fail.

- Use quality parts: Using high-quality parts can ensure that your motor runs smoothly and lasts longer. Cheap or low-quality parts can cause the motor to fail prematurely.

By following these tips, you can help ensure that your brushless motor continues to perform at its best and lasts for a long time. Regular maintenance and care can go a long way in keeping your motor running smoothly and efficiently.

Conclusion

Improving the performance of a 17.5 brushless motor can be achieved in several ways. One of the most effective ways is by adjusting the timing of the motor to suit running conditions. This can be done by using timing marks on the end of the motor’s can. By adjusting the timing, the RPM builds throughout the motor’s powerband, resulting in improved performance.

Another way to make a 17.5 brushless motor faster is by using a high-quality battery. The type of battery used can have a significant impact on the motor’s performance. A high-quality battery can provide the necessary power to the motor, resulting in increased speed and acceleration.

It is also important to ensure that the motor is properly maintained. Regular cleaning and maintenance can help to keep the motor running smoothly and at peak performance. This includes cleaning the motor and checking for any signs of wear or damage.

Overall, improving the performance of a 17.5 brushless motor requires a combination of factors, including adjusting the timing, using a high-quality battery, and proper maintenance. By following these tips, enthusiasts can achieve faster speeds and better performance from their RC vehicles.

Brushless motors work due to a simple magnetic principle: opposite (different) magnetic poles attract and opposing (same) magnetic poles repel. This simple principle creates the rotational motion of the motor. The magnetic portion of the brushless motor consists of two parts, the rotor and stator. Of course, there are other components, including bearings, the circuit board, the end-bell, solder tabs, sensors, shims, etc., but we’ll concentrate on how the rotor and stator interact with each other while adjusting timing.

The rotor is a simple metal shaft on which magnetic material is attached. This is the part of the motor that actually spins, and it’s what the pinion gear attaches to. The stator forms the bulk of the motor, and is made of stacked steel laminations wrapped with magnet wire to form three coils (in the case of a 2-pole motor, as shown here).

Energizing a coil in the motor produces a temporary magnetic field that attracts one pole of the rotor and repels the other pole. As the rotor rotates towards the temporary magnetic field produced by the coils of the stator, a sensor in the motor turns off that coil and activates the next set of coils. This continues the rotational movement of the rotor. The point in the rotation that the next set of coils is energized is key to producing a fast motor for the type of vehicle and track you’re racing. The closer the pole is allowed to be to the coil when the coil is energized, the less timing you have, but the most magnetic effect you have on the rotor because the magnetic field generated by the energized pole is closer to the pole of the rotor it is attracting. The further the rotor’s pole is from the magnetic field that is attracting it, the less powerful the attractive force will be. When you adjust timing by turning the motor’s endbell, you are adjusting the position of the sensors relative to the stator.

Energizing a coil in the motor produces a temporary magnetic field that attracts one pole of the rotor and repels the other pole. As the rotor rotates towards the temporary magnetic field produced by the coils of the stator, a sensor in the motor turns off that coil and activates the next set of coils. This continues the rotational movement of the rotor. The point in the rotation that the next set of coils is energized is key to producing a fast motor for the type of vehicle and track you’re racing. The closer the pole is allowed to be to the coil when the coil is energized, the less timing you have, but the most magnetic effect you have on the rotor because the magnetic field generated by the energized pole is closer to the pole of the rotor it is attracting. The further the rotor’s pole is from the magnetic field that is attracting it, the less powerful the attractive force will be. When you adjust timing by turning the motor’s endbell, you are adjusting the position of the sensors relative to the stator.

TIMING AND PERFORMANCE

TIMING AND PERFORMANCE

A motor with lower (less advanced) timing will produce maximum horsepower at low rpm, and a motor with higher (more advanced) timing will produce maximum power at high rpm. The best timing setting does not necessarily achieve the maximum horsepower that the motor is capable of, but rather produces the maximum horsepower within the rpm range you’e most frequently using on the track. Finding the ideal motor timing setting for your car and conditions will take a bit of trial and error, but in general, you can expect heavier cars and/or tracks with shorter straights will benefit from lower timing settings.

A heavier car and more frequent accelerations require more torque, which calls for lower timing. The additional RPM and speed a higher timing setting may provide are wasted if you don’t have long enough straights to exploit them. However, if you have a lighter car and/or are running on a track with long straights (or an oval), higher timing settings may increase your top speed and decrease your lap times. Just watch the motor temperature; the more you advance the motor’s timing, the hotter it will run. If your motor reaches 150 degrees F or higher during a run, it’s overheating and you should reduce timing, install a smaller pinion, or both. Because motor temp is so critical, an inexpensive infrared temperature is a very useful addition to your pit box.