Table of Contents

Table of Contents

- 1. Introduction to KV Rating

- 2. Technical Explanation

- 3. Mathematical Formulas and Calculations

- 4. KV Rating Comparison and Applications

- 5. Factors Affecting KV Rating

- 6. How to Choose the Right KV Rating

- 7. Common Misconceptions

- 8. Troubleshooting

- 9. Conclusion and Best Practices

1. Introduction to KV Rating

The KV rating is one of the most fundamental specifications of brushless motors, yet it remains one of the most misunderstood parameters among hobbyists and professionals alike. KV rating represents the motor’s velocity constant, specifically measuring the motor’s rotational speed in revolutions per minute (RPM) per volt applied to the motor when running unloaded.

Understanding KV rating is crucial for selecting the appropriate motor for your application, whether you’re building a racing drone, an electric vehicle, or any other project requiring precise motor control. This comprehensive guide will demystify KV rating, explain its practical implications, and help you make informed decisions when choosing brushless motors.

Key Definition: KV rating is expressed as RPM per volt (RPM/V) and indicates how fast a motor will spin at a given voltage under no load conditions.

2. Technical Explanation of KV Rating

The KV rating originates from the motor’s physical construction and electromagnetic properties. When a voltage is applied to a brushless motor’s windings, it creates a magnetic field that interacts with the permanent magnets in the rotor, causing rotation. The KV rating is inversely related to the motor’s back-EMF (electromotive force) constant.

2.1 Physical Basis of KV Rating

The KV rating is determined by several physical factors within the motor:

- Number of wire turns in each winding

- Strength of the permanent magnets

- Air gap between stator and rotor

- Number of poles in the motor

2.2 Relationship Between KV and Back-EMF

As the motor spins, it generates a back-EMF that opposes the applied voltage. The back-EMF constant (Ke) is the inverse of the KV rating. This relationship is fundamental to understanding motor behavior under load conditions.

Ke = 1/KV

where Ke is measured in volt-seconds per radian (V·s/rad)

3. Mathematical Formulas and Calculations

Understanding the mathematical relationships involving KV rating is essential for proper motor selection and performance prediction. The following formulas provide the foundation for motor calculations.

3.1 Basic KV Formula

KV = RPM / Voltage

Where:

KV = Motor velocity constant (RPM/V)

RPM = Motor speed in revolutions per minute

Voltage = Applied voltage (V)

3.2 Theoretical Maximum Speed

Maximum RPM = KV × Battery Voltage

Example: A 2300KV motor with a 11.1V battery

Maximum RPM = 2300 × 11.1 = 25,530 RPM

3.3 Current and Torque Relationships

Current (I) = (Voltage – Back-EMF) / Resistance

Torque (T) = Kt × Current

Kt = 1/KV (torque constant)

Where Kt is measured in Newton-meters per ampere (N·m/A)

3.4 Power Calculations

Mechanical Power = Torque × Angular Velocity

Electrical Power = Voltage × Current

Efficiency = Mechanical Power / Electrical Power

Pro Tip: These formulas assume ideal conditions. Real-world performance will differ due to factors like motor efficiency, temperature, and load characteristics.

4. KV Rating Comparison and Applications

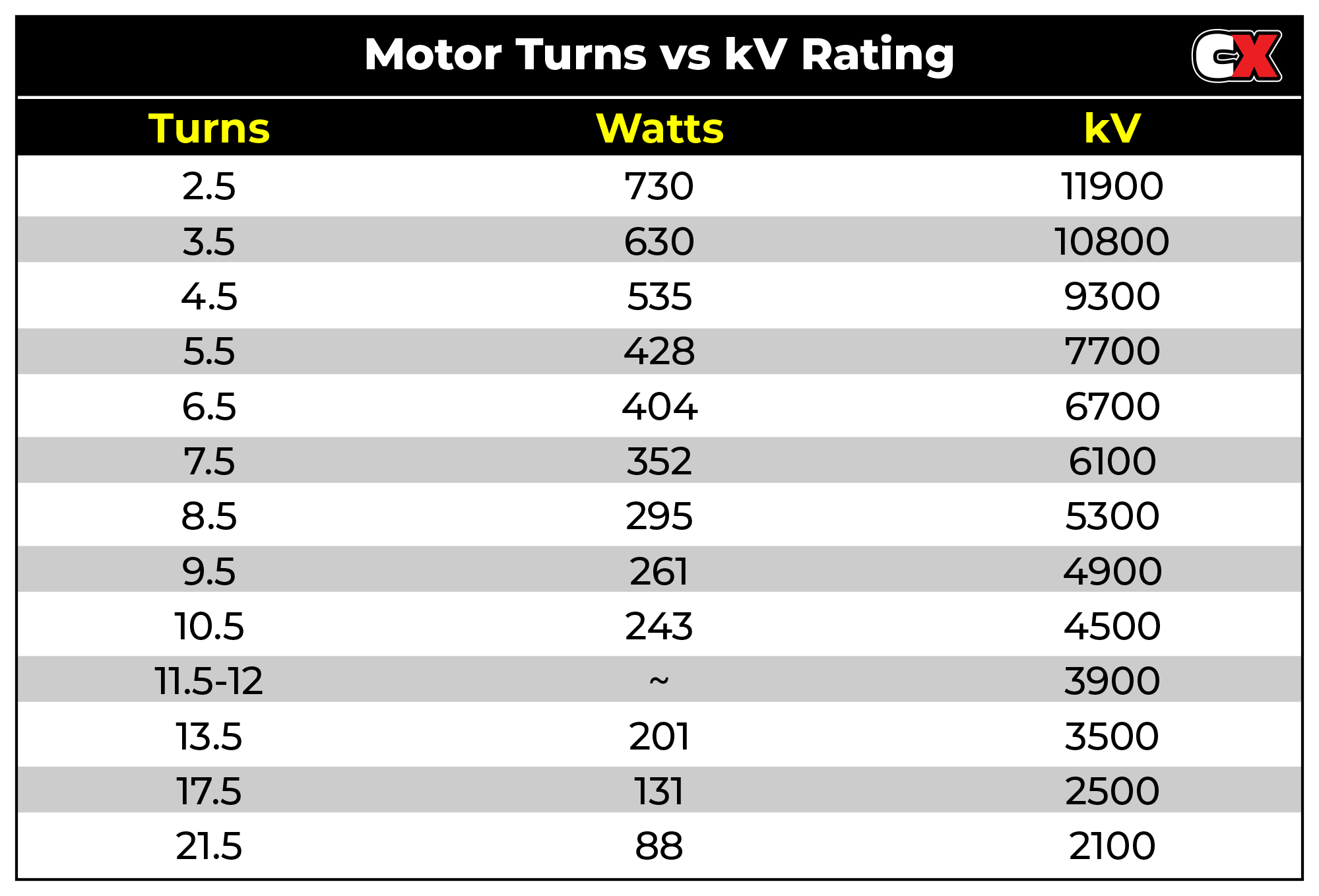

Different KV ratings are suited for different applications. The following table provides a comprehensive comparison of common KV ranges and their typical uses.

| KV Range | Speed Characteristics | Torque Characteristics | Common Applications | Typical Voltage | Propeller Size |

|---|---|---|---|---|---|

| 100-300 KV | Very Low Speed | Very High Torque | Large multirotors, heavy lift | 22.2V (6S) | 15-18 inch |

| 300-800 KV | Low Speed | High Torque | Photography drones, slow flyers | 14.8V (4S) | 10-15 inch |

| 800-1500 KV | Medium Speed | Medium Torque | Sport flying, 3D aerobatics | 11.1V (3S) | 8-12 inch |

| 1500-2500 KV | High Speed | Low Torque | Racing drones, speed builds | 14.8V (4S) | 5-8 inch |

| 2500-4000 KV | Very High Speed | Very Low Torque | Micro drones, indoor flying | 7.4V (2S) | 3-5 inch |

| 4000+ KV | Extreme Speed | Minimal Torque | Tiny whoops, ultra-micro | 3.7V (1S) | 1-3 inch |

4.1 Application-Specific Considerations

The choice of KV rating depends on your specific application requirements:

- High KV Motors: Ideal for applications requiring high speed and low torque, such as small propellers and high-speed applications

- Low KV Motors: Perfect for applications requiring high torque and lower speeds, such as large propellers and heavy lifting

- Medium KV Motors: Provide a balanced compromise between speed and torque for general-purpose applications

5. Factors Affecting KV Rating

While KV rating is a fixed specification for a given motor, several factors can influence the actual performance and effective KV of a motor system.

5.1 Temperature Effects

Temperature significantly impacts motor performance. As temperature increases, the permanent magnets lose strength, effectively reducing the motor’s KV rating. Additionally, copper windings exhibit increased resistance at higher temperatures, affecting current flow and overall efficiency.

| Temperature (°C) | Magnet Strength (%) | Effective KV Change (%) | Efficiency Impact |

|---|---|---|---|

| 25 (Room temp) | 100% | 0% | Baseline |

| 60 | 95% | +5% | Slight decrease |

| 80 | 90% | +10% | Moderate decrease |

| 100 | 85% | +15% | Significant decrease |

| 120 | 80% | +20% | Severe decrease |

5.2 Manufacturing Tolerances

Real-world motors may have KV ratings that vary from the specified value due to manufacturing tolerances. Typical variations can range from ±5% to ±10% of the stated KV rating.

5.3 Wear and Aging

Over time, motor components can degrade, affecting the KV rating:

- Permanent magnet demagnetization

- Bearing wear increasing friction

- Winding insulation breakdown

- Rotor imbalance from damage

Warning: Excessive heat, over-voltage, or physical damage can permanently alter a motor’s KV rating and performance characteristics.

6. How to Choose the Right KV Rating

Selecting the appropriate KV rating is crucial for optimal system performance. The decision process involves analyzing your application requirements, power system constraints, and performance goals.

6.1 Step-by-Step Selection Process

- Define Your Application: Determine whether you need high speed, high torque, or a balance of both

- Identify Voltage Constraints: Consider your battery voltage and ESC specifications

- Calculate Propeller Requirements: Determine the optimal propeller size for your application

- Consider Efficiency Requirements: Balance performance with power consumption

- Account for Load Characteristics: Consider static vs. dynamic loads

6.2 KV Selection Guidelines

| Application Type | Recommended KV Range | Primary Consideration | Secondary Consideration |

|---|---|---|---|

| Aerial Photography | 300-800 KV | Stability & Control | Flight Time |

| Racing Drones | 1800-2700 KV | Speed & Acceleration | Power-to-Weight |

| Freestyle Flying | 1500-2300 KV | Torque & Response | Durability |

| Long Range | 1000-1800 KV | Efficiency | Reliability |

| Heavy Lift | 100-500 KV | Torque | Current Capacity |

6.3 Voltage and KV Relationship

The relationship between battery voltage and KV rating is critical for achieving desired performance:

Optimal KV = Target RPM / Battery Voltage

Example: For 20,000 RPM with 4S battery (14.8V):

Optimal KV = 20,000 / 14.8 = 1,351 KV

Pro Tip: Always consider the motor’s efficiency curve when selecting KV rating. The most efficient operating point is typically at 70-80% of maximum RPM.

7. Common Misconceptions About KV Rating

Several misconceptions about KV rating persist in the community. Understanding these misconceptions is crucial for making informed decisions about motor selection and system design.

7.1 “Higher KV Always Means Better Performance”

This is perhaps the most common misconception. Higher KV motors are not inherently better; they are simply optimized for different applications. High KV motors sacrifice torque for speed, making them unsuitable for applications requiring high torque output.

7.2 “KV Rating Determines Motor Quality”

KV rating is simply a specification, not a quality indicator. Motor quality depends on factors such as:

- Manufacturing precision

- Material quality

- Balancing accuracy

- Thermal management

- Bearing quality

7.3 “Motors Always Run at KV × Voltage RPM”

The KV rating represents unloaded speed. Under load, motors will always run slower than the theoretical maximum due to:

- Back-EMF limiting current

- Resistive losses in windings

- Mechanical friction

- Propeller or load resistance

7.4 “KV Rating Affects Motor Efficiency”

KV rating itself does not determine efficiency. Motor efficiency depends on the operating point relative to the motor’s design parameters. A motor can be highly efficient at its optimal operating point regardless of KV rating.

Important: Efficiency depends on the match between motor characteristics and application requirements, not just KV rating.

8. Troubleshooting KV-Related Issues

When working with brushless motors, various issues can arise that are related to KV rating selection or motor performance. This section provides guidance for identifying and resolving common problems.

8.1 Common Symptoms and Causes

| Symptom | Possible Cause | Solution | Prevention |

|---|---|---|---|

| Motor runs too slow | KV too low for application | Increase voltage or choose higher KV | Proper KV calculation |

| Motor overheats quickly | KV too high, excessive current | Reduce voltage or choose lower KV | Match KV to load requirements |

| Poor efficiency | KV mismatch for operating point | Optimize KV for 70-80% max RPM | Efficiency curve analysis |

| Inconsistent performance | Temperature affecting KV | Improve cooling, monitor temperature | Thermal management design |

| Vibration and noise | Operating outside optimal range | Adjust KV or operating conditions | Proper system design |

8.2 Diagnostic Procedures

When troubleshooting KV-related issues, follow these diagnostic steps:

- Measure Actual KV: Use a tachometer and voltmeter to verify actual KV rating

- Analyze Current Draw: Measure current consumption at various loads

- Evaluate Efficiency: Calculate mechanical vs. electrical power

- Assess System Integration: Verify ESC, battery, and motor compatibility

8.3 Measurement Techniques

Accurate measurement of KV rating requires proper techniques:

KV Measurement Setup:

1. Remove propeller (unloaded condition)

2. Apply known voltage to motor

3. Measure RPM with optical tachometer

4. Calculate: KV = Measured RPM / Applied Voltage

Measurement Tip: Take multiple measurements at different voltages to verify linearity and accuracy of KV rating.

9. Conclusion and Best Practices

Understanding KV rating is fundamental to successful brushless motor applications. This comprehensive guide has covered the theoretical foundations, practical applications, and real-world considerations for working with KV ratings.

9.1 Key Takeaways

- KV rating represents RPM per volt under unloaded conditions

- Higher KV does not mean better performance—it means different performance characteristics

- KV selection depends on application requirements, not arbitrary preferences

- Real-world performance differs from theoretical calculations due to various factors

- Proper system integration is crucial for optimal performance

9.2 Best Practices for KV Selection

- Define Requirements First: Clearly specify speed, torque, and efficiency requirements before selecting KV

- Consider System Constraints: Account for voltage, current, and thermal limitations

- Plan for Efficiency: Target 70-80% of maximum RPM for optimal efficiency

- Allow Safety Margins: Don’t operate motors at absolute maximum ratings

- Test and Validate: Verify performance through actual testing, not just calculations

9.3 Future Considerations

As brushless motor technology continues to advance, several trends are worth monitoring:

- Higher efficiency motor designs

- Improved thermal management

- Better manufacturing tolerances

- Advanced control algorithms

- Integration with smart ESCs

Final Recommendation: Always match your motor’s KV rating to your specific application requirements. There is no universal “best” KV rating—only the best KV rating for your particular use case.

9.4 Additional Resources

For continued learning about brushless motors and KV ratings, consider exploring:

- Motor manufacturer specifications and application notes

- Professional motor testing equipment and procedures

- Advanced motor control theory and practice

- Thermal analysis and cooling system design

- System integration and optimization techniques

This guide provides a solid foundation for understanding KV ratings, but hands-on experience and continued learning are essential for mastering brushless motor applications. Remember that theoretical knowledge must be combined with practical experience to achieve optimal results in real-world applications.