Brushless motors have become increasingly popular in recent years due to their efficiency and reliability.

One of the most common questions that people ask about these motors is why they have twelve wires.

In this article, we will explore the reasons behind the number of wires in brushless motors and clarify any confusion surrounding this topic.

Table of Contents

Introduction: Understanding Brushless Motors

What is a Brushless Motor?

A brushless motor is an electric motor that uses electronic controllers and magnets on the rotor instead of traditional DC motor brushes to transfer power between moving parts.

This design generates torque with less friction than brushed motors, making them faster and more efficient.

Why Understanding Brushless Motors Matters

Here are five reasons why understanding brushless motors matters:

- They’re becoming increasingly popular in various industries

- They offer higher efficiency due to reduced energy loss from friction

- Their maintenance costs are lower because there aren’t any brushes or commutators that need replacing over time

- They have longer lifespans since there’s no physical contact between components causing wear-and-tear damage like in brushed motors

- The use of electronic controls allows for greater precision control over speed and acceleration compared to mechanical systems found in brushed counterparts

Learning about brushless technology will help you stay ahead as it becomes ubiquitous across many sectors while offering superior performance at a lower cost long-term.

Brushless Motor Anatomy: Stator And Rotor

The Brushless Motor: Components and Functionality

The Brushless Motor: Components and Functionality

The brushless motor is a powerful and efficient device that has revolutionized the world of electric motors.

It consists of two main components: the stator and rotor.

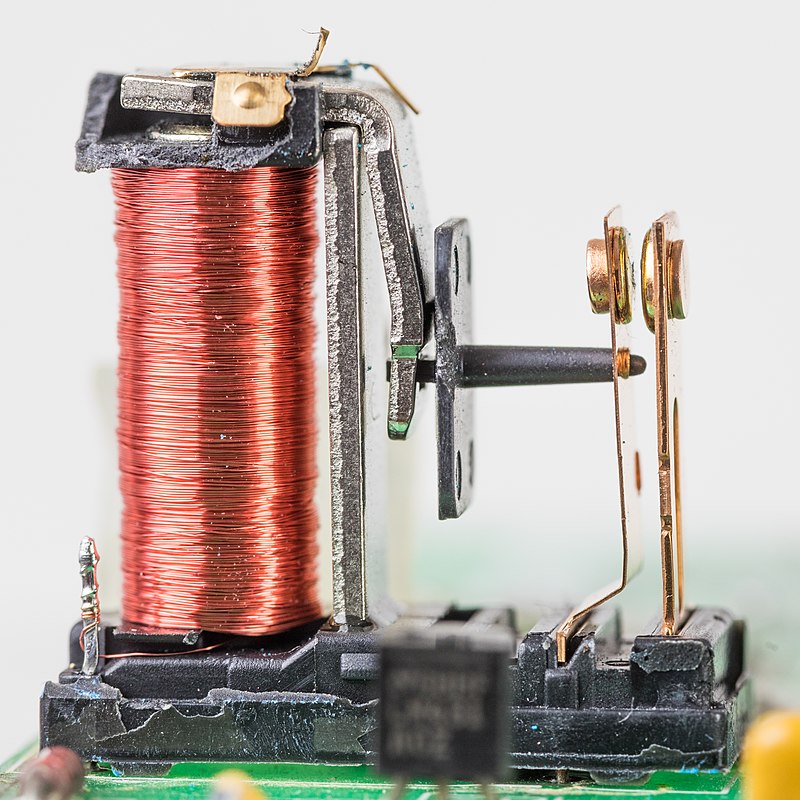

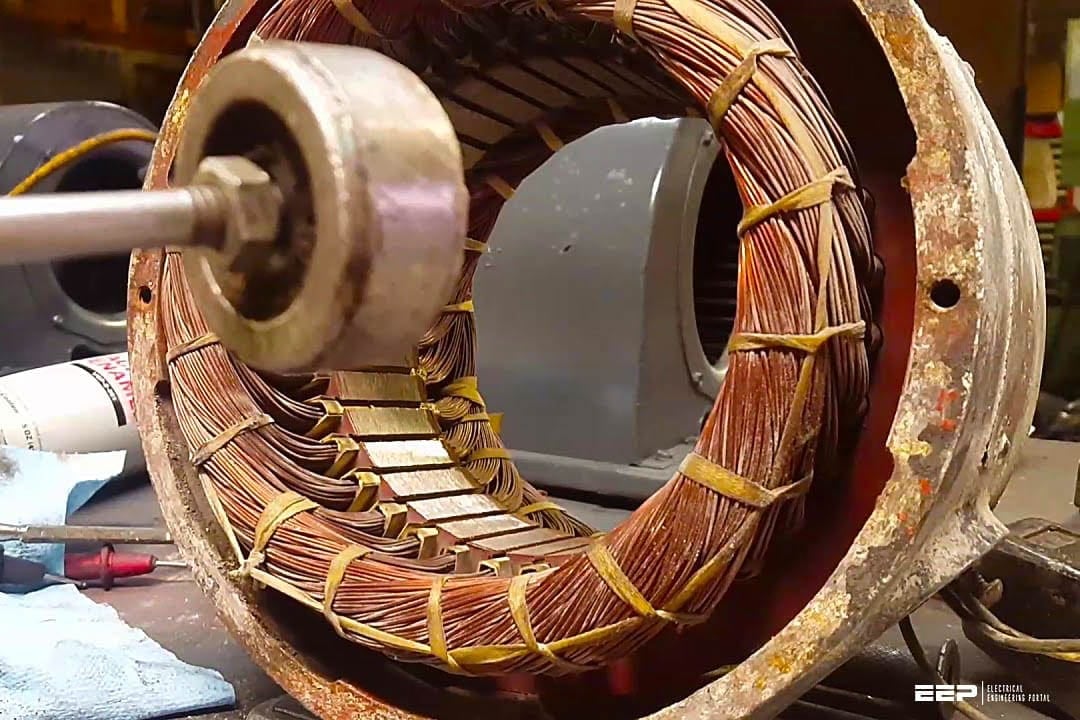

The Stator

The stator is the stationary part of the motor.

It is made up of wire coils wrapped around iron stacks arranged in a circle.

Metal links or rings connect these stacks for electrical conductivity.

The Rotor

The rotor is the rotating part of the motor.

It consists of permanent magnets on a shaft or steel core with air gaps between them and the stator core for smooth rotation without contact.

Here are some important things to remember about brushless motors:

- Torque output depends on pole count

- Rare earth magnetism improves performance

- Slot shapes vary from rectangular to trapezoidal based on voltage needs

Brushless motors are a game-changer in the world of electric motors.

They are more efficient, powerful, and reliable than their brushed counterparts.

Brushless motors are used in a wide range of applications, from drones and electric vehicles to industrial machinery and power tools.

Coil Configuration With Three Phases (A, B, C)

How Brushless Motors Work

How Brushless Motors Work

Brushless motors have 12 wires, enabling a coil configuration with three phases: phase A, B, and C.

These coils are wound in a specific pattern on the motor’s stator to create an electromagnetic field when electricity is applied.

- Three-phase power allows for more precise control over electromagnetism compared to single or two-phase configurations

Each coil in this configuration is energized sequentially by its corresponding electronic circuit on the control board.

As one phase winds down from maximum current flow (180 degrees), another begins ramping up towards it (120-degree offset).

This provides smooth torque delivery throughout operation resulting in quieter operation at higher speeds and reduced vibration.

Smooth torque delivery throughout operation resulting in quieter operation at higher speeds and reduced vibration.

Brushless motors are more efficient than brushed motors because they don’t have brushes that wear out over time.

This means they require less maintenance and have a longer lifespan.

Brushless motors are more efficient than brushed motors because they don’t have brushes that wear out over time.

Additionally, brushless motors have faster response times and can operate at higher speeds.

They are commonly used in drones, electric vehicles, and industrial machinery.

Brushless motors have faster response times and can operate at higher speeds.

The Relationship Between The Number Of Poles And Wires In A Brushless Motor

The Importance of Proper Connection Management in Brushless Motors

The Importance of Proper Connection Management in Brushless Motors

The number of poles in a brushless motor directly affects the required wires.

More poles mean more phases, each requiring its own wire for proper efficiency and control.

For instance, six poles necessitate at least six connected wires while three-phase systems require nine connections (three per phase)

External controllers also need their leads to run through these same cables

This means that proper connection management is crucial for optimal performance.

Key Points to Keep in Mind

- More poles in a brushless motor mean more phases and wires are required for proper efficiency and control

- For instance, six poles necessitate at least six connected wires while three-phase systems require nine connections (three per phase).

- External controllers also need their leads to run through these same cables.

- Proper connection management is crucial for optimal performance

When it comes to brushless motors, it’s important to keep in mind that the number of poles directly affects the number of wires required for proper operation.

Types Of Brushless Motors Based On Pole Count

Understanding Brushless Motors: Types and Applications

Understanding Brushless Motors: Types and Applications

Brushless motors are a type of electric motor that come in different varieties based on their pole count.

A motor’s poles refer to its electromagnetic coils, which can be either north or south magnetic poles that interact with permanent magnets inside the motor for motion.

Low-Pole-Count vs. High-Pole-Count Motors

Low-pole-count motors have fewer than 8 poles and operate at higher speeds but generate less torque per revolution compared to high-pole-count ones.

High-pole-count motors may have over 16 poles and excel at low speeds while producing more torque for heavy-duty workloads.

Types of Brushless Motors by Pole Count

There are different types of brushless motors based on their pole count:

- Two-Poles: Used in applications where size and weight matter most like drones.

- Four-Poles: Commonly found in small electronics requiring precision control such as printers or scanners.

- Six-Poles: Ideal for medium-sized machinery used in manufacturing processes.

Remember, the pole count of a brushless motor affects its speed and torque capabilities.

Choose the right type of motor for your application to ensure optimal performance.

Whether you’re building a drone, a printer, or a manufacturing machine, understanding the different types of brushless motors available can help you choose the right one for your needs.

Why Some Brushless Motors Have More Than Six Poles

Why Brushless Motors Have More Than Six Poles

Why Brushless Motors Have More Than Six Poles

Brushless motors have more than six poles to improve efficiency and torque output at low speeds with reduced ripple compared to lower-pole-count designs.

A pole refers to a set of magnets in the motor that creates force when electricity flows through them.

- More magnetic fields increase stability

- Low-speed torque output improves

- Durability increases due to decreased external resistance

Having more poles in a brushless motor increases stability by creating more magnetic fields.

This results in a smoother and more consistent rotation, reducing ripple and improving efficiency.

Low-speed torque output also improves with more poles.

This is because the motor can generate more force with each rotation, allowing it to maintain speed even under heavy loads.

More poles in a brushless motor means more magnetic fields, resulting in a smoother and more consistent rotation.

Finally, having more poles can increase the durability of the motor.

This is because the increased magnetic fields reduce external resistance, which can cause wear and tear on the motor over time.

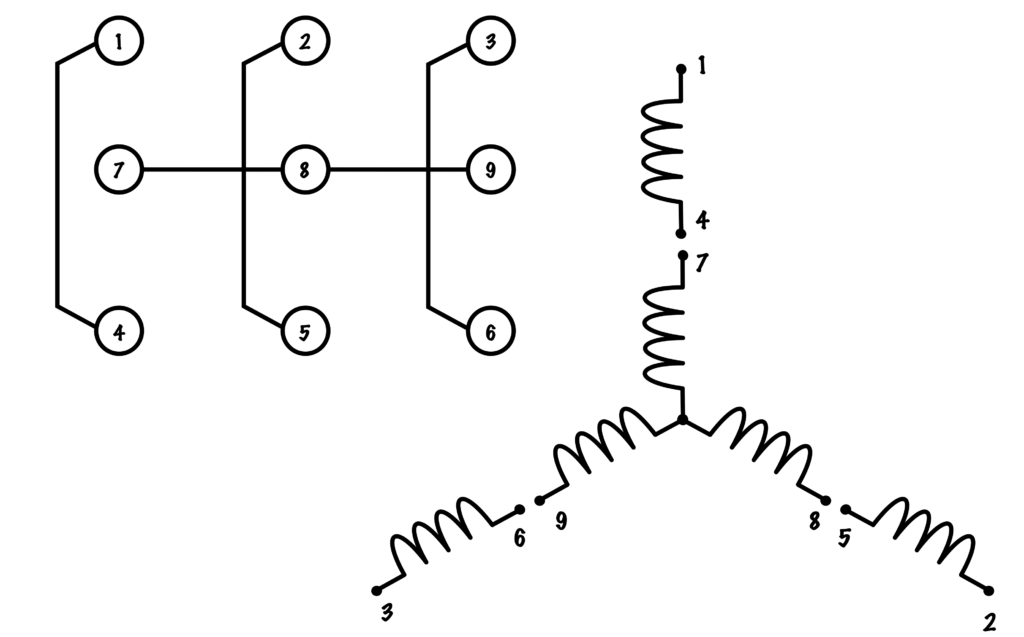

Overview Of The Delta And Wye Configurations For Three Phase Motors

Brushless Motors: Delta vs. Wye Configuration

Brushless Motors: Delta vs. Wye Configuration

Brushless motors come in two common three-phase configurations: Delta and Wye.

- The Delta configuration, also known as triangular or mesh, creates an endless loop by connecting each wire coil directly to another, resulting in consistent magnetism across all phases of power

- The Wye configuration connects individual coils at one central point before wiring out into separate phases, providing greater stability during operation and reduced voltage fluctuations

Benefits of Brushless Motors

Brushless motors offer several advantages over brushed ones:

- Quieter operation

- High speeds without mechanical brushes

Brushless motors are the future of motor technology, offering superior performance and efficiency.

With their increased efficiency and durability, brushless motors are becoming the preferred choice for a wide range of applications, from electric vehicles to industrial machinery.

The Wye configuration is ideal for applications that require high torque and low speed, while the Delta configuration is better suited for high-speed applications.

Advantages Of Using A Twelve Wire System For Higher Pole Count Motors

The Advantages of a Twelve Wire System for Brushless Motors

The Advantages of a Twelve Wire System for Brushless Motors

A twelve wire system is a popular choice for brushless motors with high pole counts.

It offers several advantages, making it ideal for applications that require high torque and precision.

Improved Efficiency

Using a twelve wire system in these motors improves efficiency by reducing resistance due to fewer turns per coil.

This results in reduced electrical losses during operation.

Increased Flexibility

This configuration allows increased flexibility when configuring winding patterns to optimize performance parameters such as power density or speed-torque characteristics.

Enhanced Control

Using a twelve wire system provides enhanced control over motor behavior through software customization.

Lower Cogging Torque

The twelve wire system leads to lower cogging torque, resulting in smoother rotation.

Reduced Chance of Overheating

The twelve wire system also reduces the chance of overheating, making it a safer option for high-performance applications.

In summary, if you need higher pole count brushless motors with improved efficiency and enhanced control over their behavior while also having lower cogging torque and less risk of overheating then the 12-wire configuration is an excellent option!

The Impact Of Reducing Electrical Resistance In The Motors Windings

How Reducing Electrical Resistance Can Improve Motor Performance

How Reducing Electrical Resistance Can Improve Motor Performance

Lowering the electrical resistance in a motor’s windings can have a significant impact on its overall performance.

By reducing resistance, less energy is lost as heat, resulting in better efficiency and a longer lifespan for the motor.

But that’s not all.

Lowered electrical resistance can also generate more power with less battery electricity, reducing current draw and operating temperatures for extended brushless motor life by minimizing wear and tear.

5 Benefits of Reduced Electrical Resistance

Here are some additional benefits of reducing electrical resistance in a motor:

- Increased Responsiveness: Lower resistance means faster response times, making the motor more reactive to changes in speed and direction.

- Improved Torque: Reduced resistance can also improve the motor’s torque, allowing it to handle heavier loads with ease.

- Boosted Speed: With less energy lost as heat, the motor can operate at higher speeds without overheating.

- Reduced Noise Levels: Lower resistance can also result in quieter operation, reducing noise pollution in the surrounding environment.

- Enhanced Precision: By reducing wasted power dissipation, the motor can operate with greater precision and accuracy.

How To Wire A Twelve Wire Brushless DC Motor Correctly

Wiring a 12-Wire Brushless DC Motor: Tips and Tricks

Wiring a 12-Wire Brushless DC Motor: Tips and Tricks

Wiring a 12-wire brushless DC motor may seem daunting, but it’s not.

With the right knowledge and patience, you can have your motor up-and-running quickly.

Identify Each Wire

Start by identifying each wire on your motor.

There are six pairs of wires with different color combinations for each pair (e.g., red/blue, black/yellow).

Divide them into three phases based on their placement within the stator:

- Phase A has two pairs of wires at 0 degrees and 180 degrees

- Phase B has two pairs of wires at 120-degree intervals from phase A

- Phase C also has another two sets at the same degree apart as that of Phase B

Follow These Five Easy Tips

Challenges In Designing An Efficient Control System

Designing an Efficient Control System for Brushless Motors

Designing an Efficient Control System for Brushless Motors

Designing an efficient control system for brushless motors is a challenging task due to various factors.

Accurate and reliable feedback sensors are crucial to ensure stability and prevent motor damage.

Selecting appropriate power electronics components such as drivers and MOSFETs requires careful attention since they handle high-frequency switching.

Feedback sensor selection is vital.

Careful electronic component selection is required.

Stable control algorithm implementation is necessary.

Challenges in Designing a Control System for Brushless Motors

Implementing a stable control algorithm that accurately controls speed and torque output while maintaining stability across different loading conditions is another challenge.

Designers must consider parameters like voltage, current, temperature, and position sensing data from feedback sensors.

Voltage regulation is important.

Conclusion: Exploring New Possibilities With Advanced Electronics

Advanced Electronics: Exploring New Possibilities with Brushless Motors

Advanced Electronics: Exploring New Possibilities with Brushless Motors

Brushless motors with 12 wires have revolutionized advanced electronics.

They offer precise and efficient control of each motor phase, resulting in smoother operation and a wider range of torque options.

Moreover, sensors can now be integrated within the motor itself to detect changes in temperature, speed, or position.

These features provide further customization possibilities for users who want to fine-tune their applications according to specific needs.

“With these advancements in brushless motors, new horizons have opened up for advanced electronics that were previously unattainable.”

Summary:

- Brushless motors with 12 wires offer more precise control

- They allow for smoother operation

- A wide range of torque options are available

- Sensors can be integrated within the motor itself

- Advanced electronic features increase customization possibilities

These advancements in brushless motors have opened up new possibilities for advanced electronics.

With more precise control, smoother operation, and a wider range of torque options, users can achieve better performance in their applications.

The integration of sensors within the motor itself also provides more customization possibilities, allowing users to fine-tune their applications according to specific needs.

“The future of advanced electronics is bright with the possibilities offered by brushless motors.”

The Brushless Motor: Components and Functionality

The Brushless Motor: Components and Functionality How Brushless Motors Work

How Brushless Motors Work The Importance of Proper Connection Management in Brushless Motors

The Importance of Proper Connection Management in Brushless Motors Understanding Brushless Motors: Types and Applications

Understanding Brushless Motors: Types and Applications Why Brushless Motors Have More Than Six Poles

Why Brushless Motors Have More Than Six Poles Brushless Motors: Delta vs. Wye Configuration

Brushless Motors: Delta vs. Wye Configuration The Advantages of a Twelve Wire System for Brushless Motors

The Advantages of a Twelve Wire System for Brushless Motors How Reducing Electrical Resistance Can Improve Motor Performance

How Reducing Electrical Resistance Can Improve Motor Performance Wiring a 12-Wire Brushless DC Motor: Tips and Tricks

Wiring a 12-Wire Brushless DC Motor: Tips and Tricks Designing an Efficient Control System for Brushless Motors

Designing an Efficient Control System for Brushless Motors Advanced Electronics: Exploring New Possibilities with Brushless Motors

Advanced Electronics: Exploring New Possibilities with Brushless Motors